Hydro power - Waterwheels

Smith Engineering manufacture high efficiency, overshot waterwheels, generating electricity from flows between 100 to 500 litres per second and heads 2 to 6 metres.

Generate electricity 24/7, efficiently and predictably from the watercourse at your premises with our innovative design of an ancient technology.

Smith Engineering waterwheels are built to a high specification following research and development in bucket design and efficiency. The novel design achieves approximately 75% water-to-wire efficiency.

To calculate total available power at 100% efficiency is:

Fall (in metres) x Flow (litres per second) x Gravity 9.81

= Power (Watts).

(e.g. 4.1 x 200 x 9.81 = 8,044 Watts)

For 75% efficiency the total available power is:

8,044 Watts x 75% = 6033 watts (6kW)

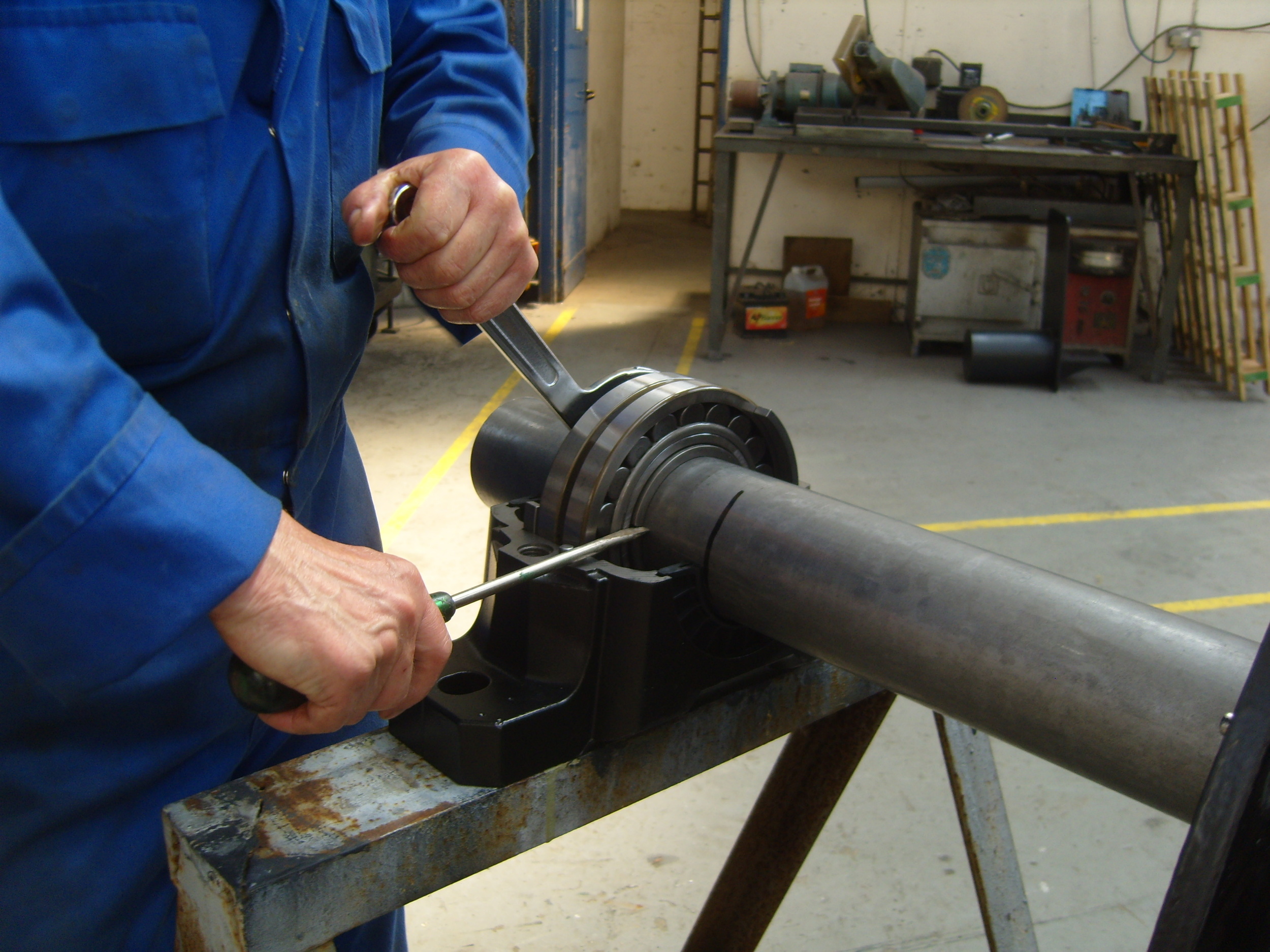

During construction, the waterwheel components can be lifted in place without the need for heavy lifting machinery, reducing installation time and health and safety risks. This also allows assembly in areas with limited access e.g. rural areas with narrow roads. Annual bearing lubrication is the only regular maintenance requirement and the modular design ensures components are easily replaced if required.

Dependent on their location, the total installation cost of Smith Engineering waterwheels is similar to micro turbines.

Key features:

Supplied as flat pack kit

Simple design - use of bolts instead of welding

Easy assembly - no requirement for special tools

Rapid assembly - minimum number of components used (approximately 2 weeks for whole system)

Cost effective materials - constructed of pre-galvanised laser cut sheet

Durable - greater than 25 years lifetime

Key benefits:

High water-to-wire efficiency - approximately 75%

Easy maintenance - only annual greasing required

Modular design ensures easy component replacement

Elegant design - attraction for visitors

Bespoke - each wheel built to customer requirements

Smith Engineering waterwheels are designed and manufactured at our factory in Maryport in Cumbria, England.

We offer a turnkey service if required and would be happy to discuss your requirements. For further information please call +44 (0)1900 815831 or email us.

6kW electricity generating waterwheel installed at The Langdale Hotel and Spa in the English Lake District.

Case Study -

The Langdale Hotel and Spa, English Lake District

Design, manufacture and installation of 6kW electricity generating waterwheel, producing 144kWh of power per day from a continuous flow of 200 litres per second, with a potential to produce 30MWh per year if in use 70% of the time.

Facts and figures:

Location: Great Langdale, Cumbria, England

Commissioned: November 2014

Output: 6 kW

Flow rate: 200 l/s

Wheel diameter: 4.1 m

Wheel width: 1 m

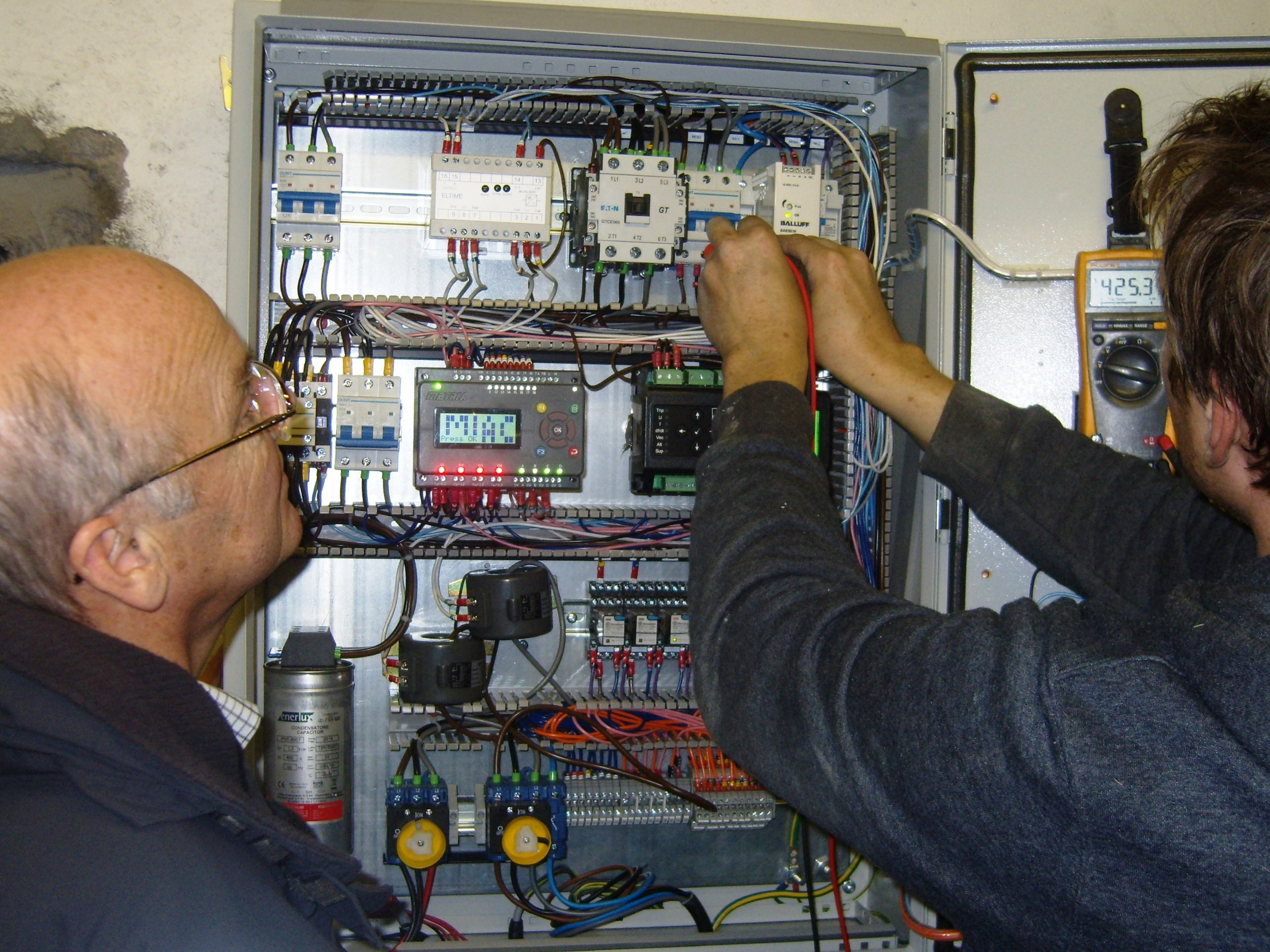

Gearbox: Brevini epicyclic 177:1 ratio

Generator: Brook Crompton three-phase, 415V induction motor, power rating of 11kW

Customer & civils: Langdale Leisure Ltd

Connection: Border Hydro Ltd

Trials: Dr Paddy Quinlan

The 4.1m diameter waterwheel is positioned in an existing water supply in one of the old wheel pits of the former gunpowder works, next to The Langdale Estate’s original turbine house which generated electricity for the estate in the 19th century.

The spokes, rims and buckets were all fabricated from pre-galvanised sheet finished with polyester powder coating. These lightweight components were easily and rapidly assembled using stainless steel nuts and bolts without the need for welding or any special tools on site. Only the wheel hub required welding and this was undertaken at our factory.

Delivery to site as a flat pack kit enabled it to be installed without the need for a large crane which would have been unable to travel down the narrow road to the site. This unique feature allows our overshot wheels to be installed in remote locations where there is restricted access.

Tests undertaken with Dr Paddy Quinlan of the University of Cumbria show that high mechanical efficiencies can be achieved from our overshot wheels. A water-to-wire efficiency of 65% was expected but the tests showed it is over 75%.

Payback at this rate should be approximately 7 years.

For further information please call +44 (0)1900 815831 or email us.

Reg Tiffin (l), Jonathan Smith (c) and David Lightfoot (r) with waterwheel installed at The Langdale Hotel and Spa.

Video

Watch the assembly of the waterwheel at Langdale in 60 seconds!

Gallery

Case Study -

Eskdale Mill, English Lake District

Design, manufacture and installation of 3.5kW electricity generating waterwheel, producing 84kWh of power per day from a continuous flow of 100 litres per second, with a potential to produce 21MWh per year if in use 70% of the time.

3.5kW electricity generating waterwheel installed at Eskdale Mill in the English Lake District.

Facts and figures:

Location: Boot, Eskdale Valley, Cumbria, England

Commissioned: July 2016

Output: 3.5 kW

Flow rate: 100 l/s

Wheel diameter: 4.0 m

Wheel width: 0.8 m

Gearbox: Brevini epicyclic

Generator: Brook Crompton three-phase, 415V induction motor converted to single-phase 240V

Video

Customer: Eskdale Mill & Heritage Trust

Watch the 3.5kW Electricity Generating Waterwheel at Eskdale Mill in action.

Timber, elevated launder: Eskdale Mill & Heritage Trust

Civils: Marcus Worthington & Co Ltd / Eskdale Mill & Heritage Trust

Connection: Border Hydro Ltd

The wheel is installed at the oldest and last working corn mill in the English Lake District, providing power for the miller’s cottage. It has been positioned adjacent to the Grade II* listed mill which has been operating for hundreds of years. It is now owned and run as a tourist attraction by Eskdale Mill & Heritage Trust, a charity run by local people, who gain a supplementary income from the power generated to cover some of the mill’s overheads and maintenance costs.

Delivery to site as a flat pack kit enabled it to be installed without the need for a large crane which would have been unable to travel down the narrow road and over the 'pack horse bridge' to the site.

For further information please call +44 (0)1900 815831 or email us.